XL-12050-1

Crafted with passion and precision, this handmade sink is a testament to traditional artistry and modern functionality. Meticulously shaped by skilled artisans, each piece is individually forged from premium materials— stainless steel—ensuring durability and a one-of-a-kind aesthetic.

Why Choose Our Handmade Sink?

✔ Unparalleled Quality – Hand-cut, welded, and polished for superior durability and heirloom longevity

✔ Custom Design Options – Tailor dimensions, materials (SS201 or SS304), thickness(1.5 to 3.0mm) and finishes(Satin,gold, rose gold,mirror,black,white,gun grey) to your exact needs

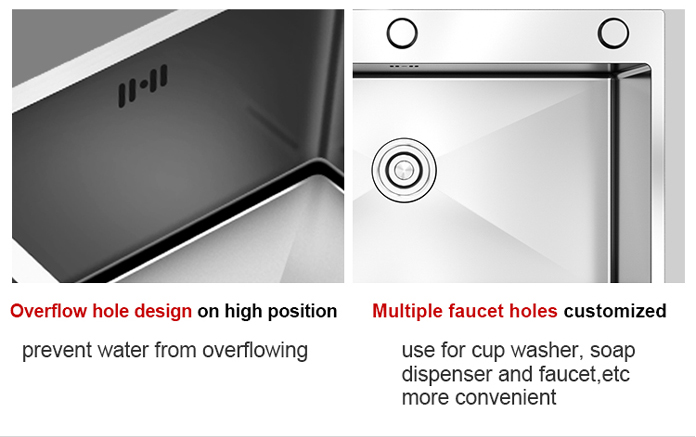

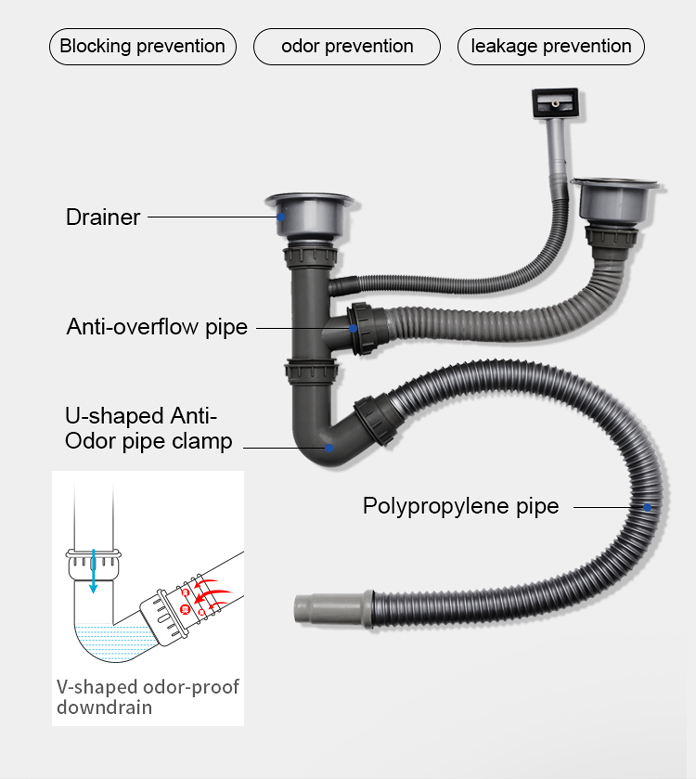

✔ Functional Artistry – Thoughtful details like reinforced basins, optimal depth, and smooth drainage

✔ Statement-Making Style – From rustic farmhouse charm to sleek modern elegance

Key Features:

Exquisite Craftsmanship: Every sink bears subtle variations in texture and form, showcasing the beauty of hand-hammered, welded, and polished details.

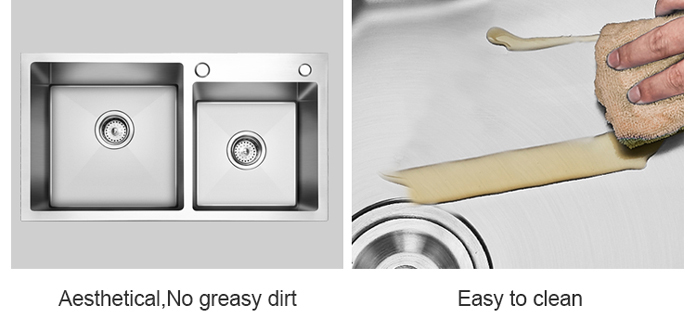

Superior Durability: Made with high-density materials and reinforced construction for exceptional resistance to corrosion, scratches, and daily wear.

Thoughtful Design: An ergonomic depth, anti-splash rim, and smooth drainage slope combine practicality with timeless elegance.

The Timeless Art of Handmade Sinks: Where Craftsmanship Meets Functionality

In an era dominated by mass production, handmade sinks stand out as unique works of functional art. Each piece is meticulously crafted by skilled artisans, ensuring superior quality, durability, and a one-of-a-kind aesthetic that factory-made sinks simply cannot match.

Why Choose a Handmade Sink?

1. Unmatched Craftsmanship

Unlike machine-stamped sinks, handmade sinks are shaped, hammered, and finished by hand. Artisans use traditional techniques—such as hand-forging, TIG welding, and precision hammering—to create sinks with exceptional structural integrity and refined details.

2. Premium Materials

Handmade sinks are typically crafted from high-quality materials, including:

-

304/201 Stainless Steel (rust-resistant and durable)

3. Customization & Unique Designs

Since each sink is made by hand, customers can request:

-

Custom sizes and depths

-

Personalized finishes (brushed, hammered, polished, or patinated)

-

Decorative elements (hand-engraved patterns, embossed textures)

4. Durability & Longevity

Handmade sinks are built to last, with reinforced construction and thicker gauge metal than most mass-produced alternatives. Properly maintained, they can become heirloom pieces passed down through generations.

Popular Styles of Handmade Sinks

-

Farmhouse/Apron Front Sinks – Rustic charm with deep basins

-

Hammered Copper Sinks – Warm, artisanal appeal with natural color variations

-

Modern Minimalist Sinks – Sleek, hand-polished stainless steel for contemporary kitchens

-

Stone Vessel Sinks – Organic textures for spa-like bathrooms

Ideal for Discerning Homeowners & Designers

Handmade sinks are perfect for:

✔ Luxury kitchens & bathrooms

✔ Boutique hotels & restaurants

✔ Eco-conscious homes (many use recycled metals)

✔ Interior designers seeking statement pieces

Caring for Your Handmade Sink

-

Copper Sinks: Allow natural patina or polish regularly for shine.

-

Stainless Steel: Use mild cleaners to avoid scratches.

-

Stone Sinks: Seal periodically to prevent staining.

Final Thoughts

A handmade sink is more than just a functional fixture—it’s a conversation piece, a work of art, and a testament to enduring craftsmanship. Whether you prefer the rustic warmth of hammered copper or the sleek elegance of hand-polished steel, a handmade sink elevates any space with its unique character.

Here’s a clear step-by-step table for ordering stainless steel sinks from our factory:

| Step | Process Stage | Details | Customer Requirements |

|---|---|---|---|

| 1 | Inquiry | Contact sales (email/phone/form). Specify: size, material (304/201 SS), style (single/double bowl), finish (brushed/satin), quantity, etc. | Provide sketches/CAD files (if custom design). |

| 2 | Quotation | We send a quote (unit price, MOQ, lead time, payment terms). | Confirm or request adjustments. |

| 3 | Contract Signing | Sign agreement with specs, delivery date, payment (30-50% deposit), QC standards. | Pay deposit (bank transfer/PayPal/etc.). |

| 4 | Production & QC | Manufacturing with progress updates. Strict QC (material test, welding, waterproof check). | Optional third-party inspection. |

| 5 | Payment & Shipping | Pay balance. We arrange logistics (sea/air/land) and share tracking details. | Provide shipping/import documents if needed. |

| 6 | Delivery & After-Sales | Inspect goods upon arrival. Warranty (1-5 years) covers defects. | Report issues within 7 days for support. |

Notes:

-

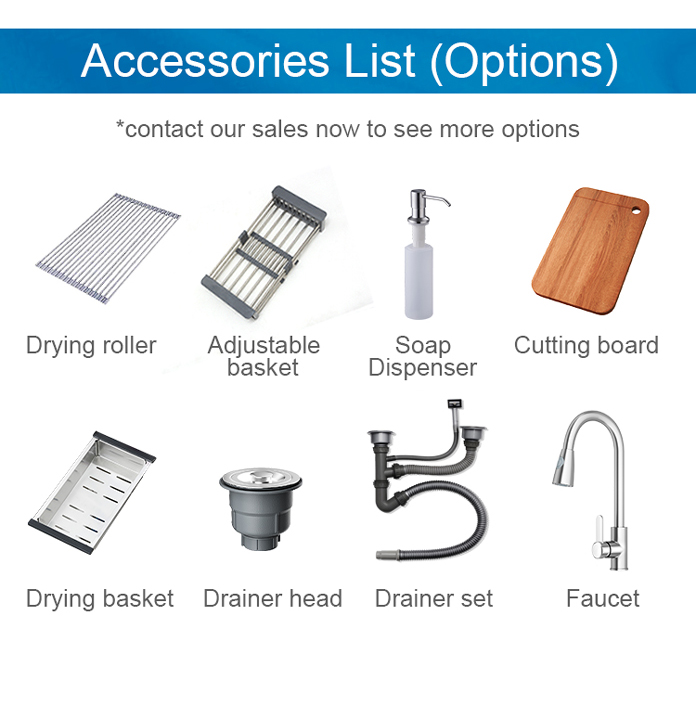

Customization: Logo engraving, anti-bacterial coating, noise-proof pads, etc. (specify early).

-

Export: We assist with CE/FDA certifications and customs clearance (extra fees apply).